There is an old saying that guides me each and every day:

Those at the top will have fire in their eyes

Those in the middle will have worry

Those at the bottom will laugh

Only with the sounds of laughter can the path be created

When you set a high target, those with ability become motivated to achieve that target. People in the middle become concerned and worry about the scale of the challenge. People without ability burst out laughing at the seemingly hopeless task.

But a target should be set so high that the world laughs at you – or it is not the right path to go down and not the right dream to follow.

We are a small company from Hanamaki in Iwate prefecture in the Tohoku region of Japan, and we have a dream to be a factory that will draw in customers from all over the world.

That dream might be so big that it makes people laugh right now, but I believe we can get closer and closer to reaching that goal if each and every employee works towards it in everything they do.

To achieve this dream we need to be a “shrewd company” that is always aware of and ahead of the dizzying changes in our business environment.

With a philosophy of always seeking to change for the better, and always backing up our philosophy with action, we are working towards achieving our dream – one step at a time.

Only by building high can you see new horizons.

Corporate Overview

| Name | UKnow Industry Ltd.. |

|---|---|

| Founded | 1994.02.14 |

| Address | 19-10-10, Higashijunichome, Hanamaki, Iwate, 025-0015 (In Hanamaki Machining and Metalwork Industry Park) |

| Phone No. | +81-198-24-0766 |

| FAX | +81-198-24-0792 |

| URL | https://uknow-industry.com/ |

| Director | Representative Director: Yasuhiro Shikauchi |

| Capital | 13 million yen |

| Capabilities | Precision machining, anodizing, powder coating, Tig weldning, waterjet cutting, assembly |

| Manufactured | Semiconductor manufacturing equipment components, liquid |

| components | crystal manufacturing equipment components, circuit board printing fixtures, medical equipment components, automotive and aeronautical related components, medical equipment components, etc. |

| No. Employees | 64 (as of 27 August 2018) |

| Site Area | 9,100 m2 |

| Building Area | 3,246 m2 |

Access

Group Companies

| Operation Details | Metalwork, assembly and related operations for the manufacture of precision measuring equipment components, sensor components, semiconductor manufacturing equipment components, medical equipment components |

|---|---|

| Address |

|

History

| February 1994 | Kyoritsu Seiko Corp. established in the Hanamaki Machining and Metalwork Industry Park with initial capital of 13 million yen. |

| November 1995 | First plant established |

| March 2000 | Acquired adjacent plant and land to expand to No. 2 plant |

| October | Established material warehouse |

| January 2001 | Built new No. 2 Plant and began surface treatment operations |

| January | Built new wastewater treatment plant |

| July | Officially recognized by the Japanese Ministry of Health, Labour and Welfare for promoting the creation of a comfortable workplace |

| October | Expanded welding plant |

| April 2002 | Received IS9001 Certification |

| April 2004 | Received IS14001 Certification |

| October | Plant upgrade |

| April 2005 | Expanded paint plant and began powder coating operations |

| May | On-site paving improvements |

| October | Expanded shot-blast plant |

| April 2006 | Expanded lathe plant |

| May | 2006 Management Innovation Plan approved and water jet cutting equipment installed |

| June 2007 | Established the “Manner Room” (smoking room) |

| June 2007 | Parking lot paint refreshed |

| October | Acquired adjacent land with plant and office |

| November | Built access to newly acquired plant |

| December | Renovated new office |

| January 2008 | Refurbishment of part of newly acquired plant |

| August 2011 | Formally notified to receive energy efficiency subsidies from relevant authorities |

| July 2012 | Area selected by Japanese government as a special recovery district from the Great East Japan Earthquake |

| March 2013 | Acquired shares of Hayase Corp. and brought them into the group. |

| November 2017 | Established new sheet metal operations and began precision metal fabrication |

| February 2019 | Changes corporate structure to a holding company and changed corporate name to UKnow Industries Corp. on 14 February, 2019. |

| 1 October 2019 | Brought Kawabe Sangyo Corp. into the group. |

| 6 November 2019 | Finished construction of Hayase Corp. Kiryu Plant |

Contributing to

the local community

-

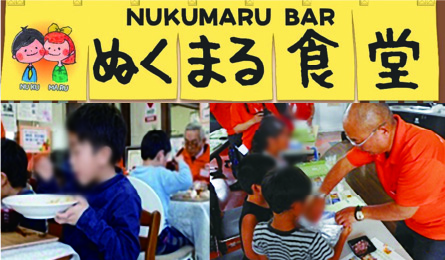

Since May 2018 we have been responsible for running the Nukumaru Canteen, a canteen set up with the Hanamaki branches of the Rotary Club and Japanese Council of Social Welfare that operates the 2nd and 4th Tuesdays every month for children in Hanamaki.

The purpose is to provide children a home-environment where they can feel safe and relaxed and they are welcome to come here and eat hand-made food, play, or do their homework. -

In addition to keeping our site beautiful, the Hanamaki Machining and Metalwork Industry Park has officially “adopted” the Toyosawa River improvement area.

We cut the grass and clean up the area around the Futatsuya drains. -

Through the “Library of the Future” or the Hanamaki Rotary Club, Mr. Shikauchi goes to junior and senior high schools in Hanamaki to talk about the value and meaning that can be derived from work.

He also went to speak to students of Hanamaki-kita Seiundai High School who will be graduating the following year and entering the workforce about how we all can learn and grow through our work. -

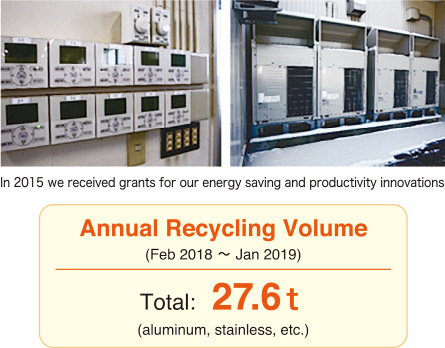

Installation of efficient inverter air conditionersg

Efforts to reduce our use of energy and CO2 emissions from our manufacturing processes has seen our energy use reduce 38% from 32.966 kl down to 20.421 kl.

Swarf and metal cutting recycling

Metal waste from our machining centers and other manufacturing facilities are separated into SUS (stainless), Al (aluminum), etc. and sent off for recycling.

-

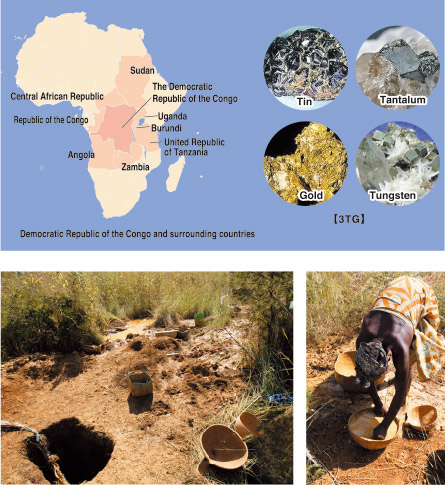

Conflict Materials refers to materials mined in conflict zones in and around resource-rich The Democratic Republic of the Congo. Tin, tantalum, tungsten and gold (3TG) are specifically restricted under the U.S. Financial Regulation Reform Act (“Dodd Frank Act”).

Minerals mined in these conflict zones are a source of funds for anti-government forces making this an international issue.

As part of our CSR (Corporate Social Responsibility) activities our policy commits us to eliminating as much as is possible the use of materials that could become a source of funds for militants.

We also work with our suppliers and customers to survey their supply chains and ensure that we do not use conflict materials and that we purchase materials responsibly.